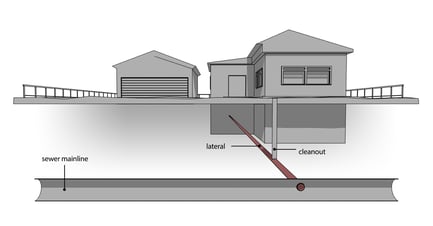

A sewer lateral is the pipe connecting a home or business’ plumbing to the city’s sanitary sewer system. These pipes typically run underneath the house or business’ property before connecting with a larger pipe, called a sewer main, under the street or other nearby area.

Wastewater from the home or business combines with waste from neighboring properties and travels through the main to eventually reach a wastewater treatment facility.

Because sewer laterals are owned by the property owner and some uncertainty exists surrounding who enforces maintenance, these pipes are oftentimes neglected, which can lead to serious complications.

Lateral Launch Crawler Inspections

Robotic CCTV crawlers with lateral launch capabilities are ideal for performing lateral inspections from the nearest manhole. These crawlers are equipped with at least two cameras: one on the main crawler body so you can see as you drive up the sewer main, and another satellite camera which can be launched into the adjoining lateral to give operators clear insight into its condition.

When inspecting from a cleanout in the house or on the property, push cameras are more commonly deployed. Equipment used is typically dependent on the inspector’s access to the lateral and the number of laterals to be inspected.

Identifying Risks

The most common issues being assessed during lateral inspections are signs of inflow & infiltration (I&I). Because sanitary sewer systems are designed to exclusively carry waste from toilets, sinks, showers, etc., I&I can add excess groundwater or rainwater to the system, thereby risking an overflow and diminishing the city’s treatment capacity. Sanitary sewer overflows (SSOs) can spill untreated sewage out into streets, parks and bodies of water, exposing the community to bacteria and creating risk for disease.

Beyond identifying signs of I&I, operators look for other defects in the lateral, including cracks, blockages and signs of deterioration. They also inspect for cross bores, ensuring other utilities installed with trenchless technology haven’t been drilled into the lateral itself, causing structural damage, and increased likelihood of blockages, and, in extreme cases, the risk of an explosion when a gas line cross bore is breached within a sewer lateral.

Enforcing Maintenance

Laterals may be made from clay, cast iron, or high-density polyethylene (HDPE)—the latter used commonly today for its durability and low cost—and may present different risks depending on the age and material.

While lateral inspections have long been overlooked, they are gradually becoming more commonplace, specifically as the posed risks and high cost of repair become more apparent. Laterals most often end up being inspected by cities before they take over a new pipe, as to avoid responsibility for one that’s already in poor condition; or when a home or business experiences a back up, cities will perform an inspection to determine who is responsible for repairs. Some cities have even developed programs to clearly outline maintenance strategies and requirements for this essential underground infrastructure.

WinCan software makes it easy to store, share and analyze your sewer inspection data, with mapping features and asset-management integrations available to ensure every part of the wastewater system is maintained. Request a free demo today to learn more: