As extreme weather events increase around the globe, cities are looking to create more resilient infrastructure to withstand and protect against floods, hurricanes, wildfires and other high-risk events. In addition to climate change, many municipalities already face I&I challenges, and aging infrastructure puts strain on local wastewater teams. When operators can’t keep up with routine maintenance and inspection, collection systems are at a higher risk of failure, and they stand little chance against significant weather events.

But artificial intelligence (AI) is revealing itself to be invaluable for wastewater applications involving not only data collection and inspection but also data management, infrastructure design and real-time management. With a variety of resiliency applications in the wastewater industry, AI can help solve some of the most significant bandwidth and workflow issues utilities face today.

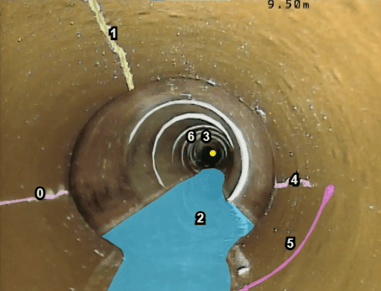

Hydraulic Modeling & AI Sewer Monitoring

.png?width=374&name=WinCan3D_1%20(1).png)

Sewer infrastructure has evolved steadily over the years, and the use of AI technology in designing and maintaining new collection systems was a natural next step in that evolution. When extreme weather strikes, sewer infrastructure is at a much higher risk of backing up or failing. But by pairing 3D-modeling with AI that can learn to analyze and predict outcomes, engineers can look at the potential effects of different weather events on collection systems.

It all starts out in the field, where sewer teams can use WinCan to collect data from laser scanning, photogrammetry, simple measurement of pipe length and diameter, and XYZ sensors. With this data on-hand, engineers can build 3D models for use in the creation of "digital twins." Digital twins combine these models with operating parameters (e.g. pump station capacity, treatment capacity) and real-world inputs (flow measurement, level measurement) to essentially run a real-time simulation. That simulation, when combined with the machine learning that happens as the AI observes and interprets previous dynamic situations, then becomes a tool for real-time management and predictive analysis.

Hydraulic and hydrologic modeling are two predictive processes that use digital twins and real-world water physics engines to simulate the performance and potential failures associated with infrastructure. Where hydraulics deals with the motion of liquids in a confined space, hydrology is the study of rainfall and runoff. Together, these not only simulate the impact of rainfall and storm-related I&I on infrastructure, but they also represent the variability in water movement into and throughout a system, exposing potential risks. The ultimate goal of a digital twin is for the model to ingest real-time data from SCADA (supervisory control and data acquisition) systems, such as flow sensors and level sensors, to monitor events as they unfold so that operators can react in real time to avoid critical failures. This is where AI begins to help shape the future of disaster preparedness and response.

As AI ingests real-world data and begins to understand how a system responds under different loads and stresses, that machine learning can be applied to more quickly identify crucial indicators of failures and even take autonomous action to adjust flow controls and prevent overflows or backups. In this way, engineers can design infrastructure that not only better prepares municipalities for extreme weather, but uses integrated AI to identify and react to an influx of runoff. This is essential to monitoring system function before, during and after extreme weather events.

AI Processes Sewer Data Faster

Predictive analysis isn't just for the design stage. It's equally useful for analyzing existing systems and how they'll perform under certain circumstances (weather, population growth, internal failures). Municipalities need to be able to continue predictive analysis as they maintain new and existing systems in a way that ensures they can withstand potential extreme weather threats. Luckily, AI offers a variety of solutions to sewer professionals, from flow monitoring and runoff analysis to expediting inspection workflows via AI-powered defect coding.

Furthermore, AI has been applied to the inspection process, as with WinCan’s Sewermatics, and it’s learning to quickly and accurately identify defects and accurately code them to different inspection standards. AI-powered automation makes processing inspection data faster than ever, getting data from the field to the web and into the hands of the people who need it. Automated technologies can bring essential insights, such as sewer condition and maintenance frequency, to the forefront of any project. This helps operators and engineers identify potential hazards and schedule preemptive rehabilitation.

An example of this is the one-click, bidirectional data transfer between WinCan VX and Esri’s ArcGIS, which gives operators the ability to populate sewer maps with observations and use a heat map to determine at-risk areas. This can be done before a severe weather event to identify areas of potential failure, or it can be done after the weather dies down, aiding the recovery and rehabilitation process. Paired with Sewermatics AI defect coding, the flow of data and decision-making becomes smoother and nearly hands-free, with highly accurate coding, automated data entry, and full data visualization capabilities.

Schedule a Sewermatics consultation to learn how WinCan AI is making a difference for inspection teams: