Balancing the bandwidth of essential utilities can be like walking a tightrope. Employee salaries, equipment costs and a variety of operational expenses are just a few of the bandwidth constraints municipalities face. To mitigate these constraints, water utilities are turning to digital, cloud-based solutions that not only help cut down time per inspection but also eliminate various manual tasks. With the help of AI and integrated technology, utilities can do more with the employee bandwidth and equipment they already have.

Unload Your Servers Into the Cloud

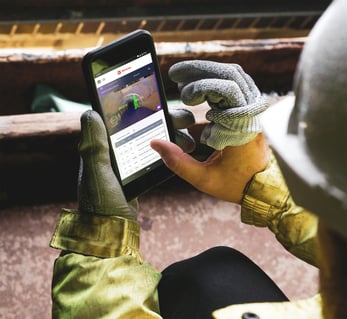

Cloud solutions are known for their data security and often large amount of data storage, but they also provide utilities with access to projects on-the-go, from phones, laptops or tablets. This enables teams to adopt more flexible workflows that allow them to jump in and out of projects at any time, making it easy to meet strict reporting timelines. From the cloud, data can be packaged into highly detailed deliverables that are sent and received within seconds without the need for USB drives or manual transfer. In many ways, the cloud frees up utility bandwidth by streamlining many of the traditional cumbersome data tasks, alleviating water teams from the restrictions of local servers.

Streamline Work Order Tasks

There are a couple of ways utilities can go about trimming down the lifespan of work orders to create more bandwidth for their water teams. One is to bring the entire work order lifecycle into one platform, where they can be created, tracked, reviewed, approved and completed all in one place. Alternatively, if using more than one software solution to manage asset data, work orders and GIS, many of these tasks can be streamlined with software integrations that automate data transfer or trigger custom automations within third-party platforms.

Automate Observation Coding

Many sewer inspection workflows leave operators along busy roadways, slowly coding observations as they conduct the CCTV inspection. While this has the potential to help operators complete inspections all at once, it also requires the operator’s full, hands-on attention, slowing down the collection process and adding pressure that can affect accuracy of coding results. The solution is to let AI make quick work of observation coding tasks.

Sewer inspection software has made the job progressively simpler, first creating an intuitive hub for data and then providing single-click solutions for automation. Today, AI can fully code a work order worth of inspection videos in less time than it takes a human operator to code a single pipe. And with the wastewater industry finding even more intricate ways for AI to enter the workflow, automation will no doubt cut down bandwidth constraints at every level of utility management.

Sewer inspection software has made the job progressively simpler, first creating an intuitive hub for data and then providing single-click solutions for automation. Today, AI can fully code a work order worth of inspection videos in less time than it takes a human operator to code a single pipe. And with the wastewater industry finding even more intricate ways for AI to enter the workflow, automation will no doubt cut down bandwidth constraints at every level of utility management.

Integrate Equipment and Software

Today’s technology is bringing equipment and software closer and closer together. In fact, many equipment brands are bridging the gap with integrated solutions that send data directly from the camera to the cloud. This cuts down the amount of time between inspections, creating more efficiency throughout the operator’s day and staging data for rapid processing via AI or an office-based coding team.

WinCan’s AI is growing more advanced every day, and with the recent launch of Envirosight’s Quickview 360, it’s already begun integrating with cutting-edge hardware. Get in touch to learn how you can get more out of our team’s bandwidth.