Sewer inspection software doesn’t exist in a void: It is only as valuable as the data you collect – and the equipment it integrates with. Smart system operators seek out flexible software that lets them pick the right equipment for the job, regardless of manufacturer.

Software that allows for direct integration, embedded video, and file conversion create more flexible, efficient workflows, saving sewer teams money and resources on the job. Because the faster inspection media can get where it needs to go, the sooner operators can get to the next manhole.

Today’s infrastructure assessment industry has more technology options than ever, from tried-and-true methods to advancing technologies.

But sewer equipment can generally be divided into two key groups:

1. Full-entry equipment that enters the sewer pipe and navigates from one manhole to the next.

- 2. Partial-entry equipment that enters a manhole but not the pipe itself.

The latter is most useful in conducting preliminary inspection. However, full-entry sewer equipment, traditionally a sewer crawler, is often required for more complete inspections.

Full-Entry Equipment

Sewer Crawlers

The sewer crawler is among the most popular pieces of sewer equipment due to its versatility. Outfitted with lighting and an articulated video camera, crawlers use wheels or tracks to drive through pipes of varying sizes. They are controlled remotely and give operators a real-time view of a pipe's interior condition.

Sewer software connects with crawlers to create a channel for inspection media and data to flow. Pipe crawlers are designed with versatility in mind, featuring wheels that can be changed out to tackle different obstacles. Meanwhile, software like WinCan can connect to the crawler’s on-screen display (OSD) to provide operators with easy access to essential metrics. With the ability to ingest side-scanning and laser profiling data, sewer software can provide a means of analyzing media from a range of brands and equipment technologies.

Push Cameras

Push cameras are comprised of a camera head attached to a cable. Propelled through a pipe manually, push cameras have limited ability to steer or center an image within a line. This makes them a better option for smaller pipes, such as sewer laterals and drain pipes, while crawlers take on mainline inspections.

Like sewer crawlers, push cameras provide a live feed of video, from which operators can record or capture photos. This inspection media is transferred into WinCan the same way it would be in the case of a crawler.

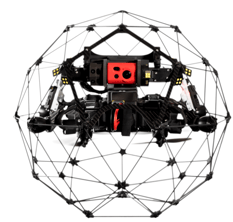

Drones

One of the latest developments in sewer inspection is full-entry drones, designed to fly through large-diameter pipes to remotely conduct inspections. Though a relatively new technology in wastewater, drone companies are slowly stepping into the industry as an alternative to crawlers. And while the long-term implications of drone inspection are still unclear, sewer inspection software like WinCan has already developed the ability to ingest drone-captured inspection media at the touch of a button. Inspection drone companies promise faster, more affordable inspection of large-diameter pipes, and sewer software is evolving to back it up.

Partial-Entry Equipment

Pole Cameras

Pole-mounted camera systems provide operators a fast, affordable way to inspect manholes and the pipe sections connected to them. Using a high-intensity lighting system and variable zoom, pan and tilt functions, pole cameras can help operators avoid confined space entry. They are also ideal for viewing pipes that are too deteriorated for a sewer crawler to traverse. Inspection media from pole cameras can be fed directly into WinCan, where users can log observations and provide condition ratings or work orders to rehab and repair or cleaning teams.

Manhole Scanners

Manhole scanners can gather a wide variety of data and visuals that support the inspection process. Though designs vary, most manhole scanners utilize a head outfitted with one or more cameras and sensors, which is then lowered into a manhole. As the camera head descends, it captures footage and geometric data that can be brought into sewer inspection software for deeper analysis. For instance, in WinCan, manhole scans can be used to build a 3D model of the manhole to gain insight into any deformations or structural damage.

Sewer inspection software like WinCan is designed to help teams collect, process and analyze the data captured by sewer equipment, and the better software integrates with equipment, the easier it is for inspection teams to get jobs done quickly and efficiently. Learn how WinCan integrates seamlessly with industry-leading equipment brands by scheduling a demo: