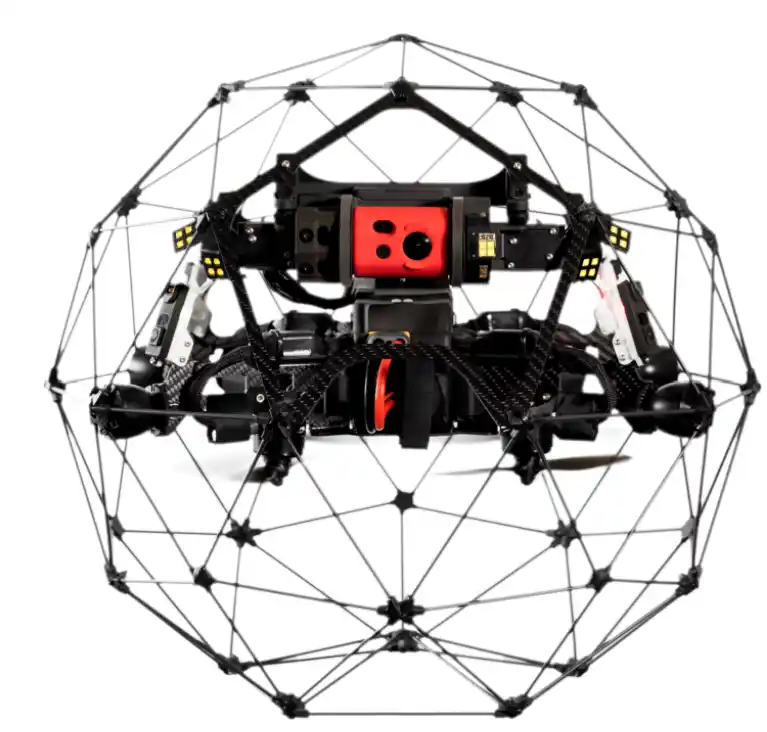

RO-KA-TECH 2025 in Kassel proved to be a resounding success once again, with a joint exhibition appearance by iPEK and WinCan.

This year's trade fair once again offered exciting insights into the latest developments in the sewer inspection industry and served as an ideal meeting point for partners, customers, and industry professionals from around the world. With a wide range of innovative solutions and a strong international presence, both iPEK and WinCan set new benchmarks.

Click here for a little video recap from the RO-KA-TECH 2025:

.webp)