/Rehab-Planning-Banner.jpg?width=600&height=320&name=Rehab-Planning-Banner.jpg)

Planning a sewer rehab project means weighing many factors for each asset: location; defect type, quantity and severity; surface obstructions; pipe material and age; and more. From his early days in the municipal world, WinCan Business Manager Mike Russin recalls using highlighters with maps tacked to the wall. “It used to be a huge hassle,” he says. “We’d watch VHS tapes, find the spot in need of rehab, use different color highlighters to mark what kind of rehab was needed, and then take the map into the engineer's office at the end of the month to get approval. There were so many hoops you had to jump through.”

WinCan, the sewer industry’s leading inspection reporting and asset management software, is now available with a new Rehab Planning Module (RPM). WinCan RPM allows anyone in charge of a collection system to utilize inspection images, video footage, condition data and maps to build and budget a rehab plan. “WinCan’s Rehab Planning Module takes the hassle out of planning your rehab efforts,” says Russin. “It makes a complicated task simple.” That simplicity is evident in WinCan RPM’s four-step process:

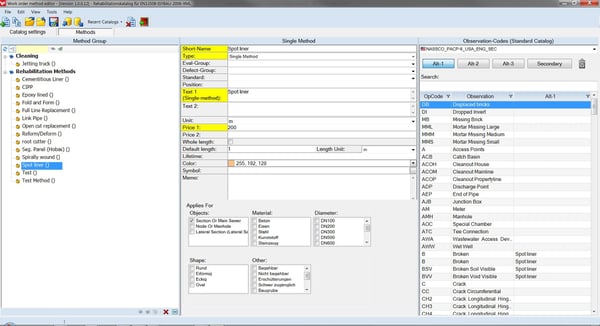

1. Build

With WinCan RPM, you first build a catalog of rehab methods. This catalog includes vendors, pricing and descriptions, and WinCan references it when calculating the cost and viability of potential rehab strategies. Once the catalog is built, it's easy to update as market prices change. The catalog can include high- and low-cost options, as well as ancillary services like jetting. “You’re starting with a blank canvas, so you can choose what picture you want to paint,” says Russin. “You can build single-method repairs or sequential repairs. Single-method repairs are just that; you want to jet a line so you select jetting and the module estimates the cost. Sequential repairs allow you to plan the same series of tasks over and over. So, if you want to do a full CIPP liner and you need to clean, TV the line, install the liner, and then reinstate laterals, a sequential repair can plan and budget all of that with one button.”

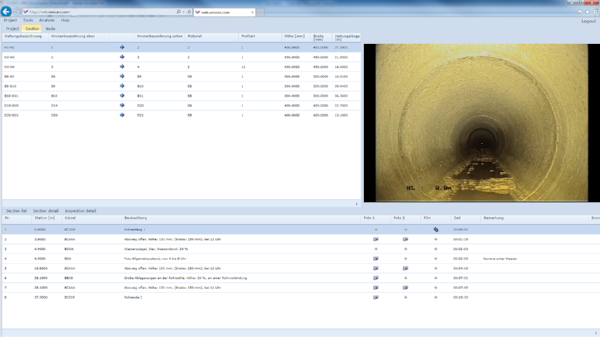

2. Analyze

Next, you specify the data set for which you want to develop a rehab plan. This can be native WinCan data, or standards-compliant data imported from other sources. When data is imported, WinCan RPM validates it against the relevant standard. (WinCan supports over 50 standards.) During validation, the user is alerted if information is missing or non-compliant. “We can take data from anywhere and make it clean and useable,” says Russin. “It won’t fix miscategorized defects but it will make sure that everything your standard requires is in the data, giving you something that can be easily and reliably analyzed.”

3. Visualize

WinCan RPM maps proposed rehab strategies for easy visualization—either natively in WinCan, or in ESRI's ArcGIS. When overlaid on satellite imagery, this makes it easy to identify problem clusters, visualize a plan of action and communicate the strategy to other stakeholders. “Using either an ArcGIS integration or the native WinCan Map functionality, you can search for defects line by line,” says Russin. “Or, you can build heat maps to see where your worst defects are concentrated. You can even search everything within a certain radius, so if you have one really bad line that needs a lot of work, you can find other problems in the area to repair at the same time. This is great for limiting traffic and service disruptions.”

/Analyst%202.jpg?width=600&name=Analyst%202.jpg)

4. Plan

By weighing benefits against cost for a variety of rehab scenarios, WinCan RPM develops an optimized plan in a way that would be time-consuming or impossible to do manually. You can quickly compare high-cost/high-impact strategies against more expedient alternatives, and then filter out defects from your data set based on severity or concentration. Once a final plan is determined, WinCan RPM generates a report detailing each repair and its cost, along with a total cost for the plan—ideal for presenting to a city council or budget committee. “When you’ve built your plan, you can take it straight into the budget meeting,” says Russin. “The WinCan report includes line items for each separate repair strategy. This is perfect for contractors with customers who demand an itemized cost estimate for repair and maintenance work.”

WinCan RPM also has a mass planning feature. If you want to build a plan to address every instance of a certain defect, the software aggregates them all and assigns the specified strategy. “Say you want to build a root control plan,” says Russin. “You want to foam the fine roots and cut all the bigger ones. WinCan RPM sorts through all the defects in your collection system, filters them and builds you a budget for how much that plan would cost—complete with locations, defect categories and itemized pricing.”

As with WinCan itself, the goal of WinCan RPM is to optimize the process of sewer operation and maintenance. “Our goal is always to make things simpler,” says Russin. “Managing a collection system, particularly a large one, is a complicated job; you’ve got so many balls up in the air and when you drop one, there are huge consequences. WinCan RPM takes the complexity and hassle out of planning and budgeting repairs, letting contractors and city managers focus on just getting the work done.”